Umshini Wokubumba Umumo Wekhwalithi Engcono Kakhulu we-EPP

I-EPP(I-Polypropylene Enwetshiwe)

I-EPP(I-Expanded Polypropylene) iwuhlobo lwezinsimbi eziyinhlanganisela ye-crystalline polymer/gas, nokusebenza kwayo okuhle kakhulu ukuze ibe ukuvikelwa kwemvelo okukhula ngokushesha kakhulu kanye nezinto zokufakelwa.

Ukusebenza Okuyinhloko

1.Ukumuncwa kwamandla: ngenxa yokuthi imikhiqizo ye-EPP inesakhiwo esikhethekile se-bubble pore, ingakwazi ukumunca amandla avela ngaphandle kahle, futhi ingavimbela ukucindezela kahle kakhulu.

I-2.Ukuvuselela kabusha: Imikhiqizo ye-EPP ukuguquguquka okuhle ingasetshenziswa ngokuphindaphindiwe, hhayi ukuphuka kalula.

Idatha Yezobuchwepheshe

| Into | Iyunithi | Uhlobo/Idatha Yobuchwepheshe | ||

| Idatha ye-PSZ1214EP | Idatha ye-PSZ1218EP | |||

| Isikhunta Dimension | mm | 1500*1300 | 1950*1300 | |

| Ubukhulu bomkhiqizo | mm | 1400*1200*330 | 1800*1200*330 | |

| Ubuncane Besikhunta Ukuqina | mm | 220 | 220 | |

| Isifo sohlangothi | mm | 210-1450 | 210-1450 | |

| Isixhumi esibonakalayo esikhwezayo | Impahla eluhlaza | / | I-DN40 | I-DN40 |

| I-Steam | / | I-DN100 | I-DN100 | |

| Umoya ocindezelwe | / | DN65 | DN65 | |

| Amanzi okupholisa | / | I-DN80 | I-DN80 | |

| Ukukhipha amanzi | / | I-DN150 | I-DN150 | |

| Ukungenisa umoya | / | I-DN80 | I-DN80 | |

| Ukusetshenziswa | I-Steam | Kg/umjikelezo | 6/13 | 10/15 |

| Umoya ocindezelwe | m3/umjikelezo | 1.3 | 1.5 | |

| Amanzi okupholisa | Kg/umjikelezo | 60-100 | 150-180 | |

| Umthwalo oxhunyiwe | I-Hydralic motor | Kw | 7.5 | 7.5 |

| Iphampu ye-vacuum | Kw | 5.5 | 7.5 | |

| Isisindo somshini we-Appr | Kg | 5700 | 7500 | |

| Ubukhulu bebonke | mm | 4600×2140 ×3100 | 5000×2450 ×3500 | |

Inkambu yohlelo lokusebenza

Imikhiqizo ye-EPP esetshenziswa kabanzi embonini yezimoto, efana ne-car bumper, i-car side shockproof core, umnyango, isihlalo semoto esithuthukisiwe, njll.

Imikhiqizo

Umshini Wokubumba Umumo we-EPP

1.Ukwakhiwa kwensimbi eqinile okucutshungulwa ngokufakwa kwezinga lokushisa eliphezulu, ukwelashwa kokushisa, indawo esuswe ukugqwala nge-sandblast futhi ifuthwe ngopende ovimbela ukubola.

I-2.Control system ithatha i-Japan PLC ne-English touch screen ukuze isebenze kalula futhi ikhiqize ngokuzenzakalelayo.

3.Izingxenye zemishini ezisezingeni eliphezulu nezizinzile, njengama-valve ase-German Burkert angle-seat valves.

4.Ukonga amandla ngosayizi womshini oklanywe kahle, imigqa yamapayipi ukubona umfutho we-steam osheshayo ukhula futhi wehla.

I-5.I-high flow hydraulic drive ene-double hydraulic cylinder, eyenza umshini usebenze ngokuqhubekayo futhi ukhiye ngokuqinile.

6.Umshini ungahlonyiswa ngohlelo lwe-vacuum eyakhelwe ngaphakathi, futhi kukhona nokufinyelela ohlelweni lwe-vacuum ephakathi.

I-7.Igumbi lokuphakela kabili lokuphakela ngokushesha ukuze unciphise isikhathi somjikelezo.

I-8.I-valve yokulinganisa yokulawula umusi ozinzile.

I-9.Imilenze yomshini we-zinc enwetshiwe iyakhethwa kukhasimende ngokufaka umshini emhlabathini okhethekile.

10.Imilenze yomshini kanye nesiteji kuyakhethwa.

IMISEBENZI OMQOKA YALOMSHINI

Ukwamukela umkhiqizo wosayizi abahlukene, lo mshini womjovo unezinhlobonhlobo zepuleti lesikhunta, i-min, ubukhulu buzungeze u-600 × 800 mm kanye nobukhulu.Ubukhulu bufika ku-1200 × 1400 mm.Lo mshini ufakwe uhlelo lwe-hydraulic olunezinyathelo ezimbili, uhlelo lokuphakelayo olucindezelweyo, kanye nesistimu yamandla emaphakathi, i-damper yokusiza, ithangi lamanzi elicindezelayo, isistimu ye-condensation, uhlelo olulawulwa yikhompyutha, uhlelo lokulawula inqubo yedijithali kanye negumbi le-steam.

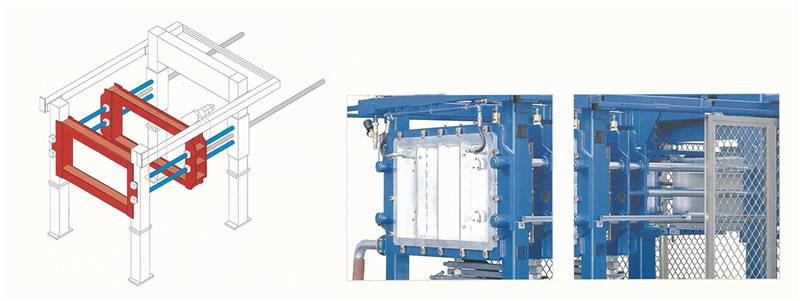

UKWAKHIWA KOMSHINI

Lolu hlelo aludingi ukuthambisa.I-hydraulic cylinder ifakwe ezinhlangothini ezimbili ze-doom ngamandla okubamba isikhunta.Idome elingenabala lingabamba ukushisa.Ukuvulwa kwesikhunta kanye nokuvalwa kwesikhunta kulawulwa uhlelo lwekhompiyutha olungaqinisekisa ukunemba okungcono kakhulu kokudla.Ukunyakaza kwe-mold ejection kulawulwa isistimu yokukhipha ukuze inikeze ikhwalithi engcono kakhulu yomkhiqizo onembayo phakathi nenqubo yokukhipha.

UKUHLELWA KWALOMSHINI

Lo mshini wakhiwe njengendawo evulekile enezinhlangothi ezintathu.Lo mklamo wendawo evulekile uzoqinisa inqubo yokushintsha isikhunta futhi opharetha bangashintsha isikhunta kusukela ngaphambili, emuva nezinhlangothi ezimbili zalo mshini.Futhi, lo mshini ungabekwa ngqo phansi ngaphandle kokusetha noma iyiphi inkundla.Ukuvikela ukuphepha kwabaqhubi, lo mshini ufakwe umnyango wokuphepha kanye nesistimu yokuphepha.

UHLELO LOKUKHUMBA

Lesi sikhunta senziwe ngefomethi yepuleti elineziqephu ezintathu.Amandla engeziwe angagcinwa ngaphandle kokubhujiswa ngakho-ke, ipuleti lesikhunta lingasetshenziswa kakhulu.Izikhonkwane zomholi kanye nesibhamu se-spray zifakwe ngaphakathi kwamapuleti ahambayo esikhunta ukuze kuqinisekiswe ukuphepha kokusebenza.Ukunciphisa isikhathi sezithombe, lolu hlelo luhlinzeka ngokufaka isikhunta ngokushesha kanye nesistimu eshintshayo.

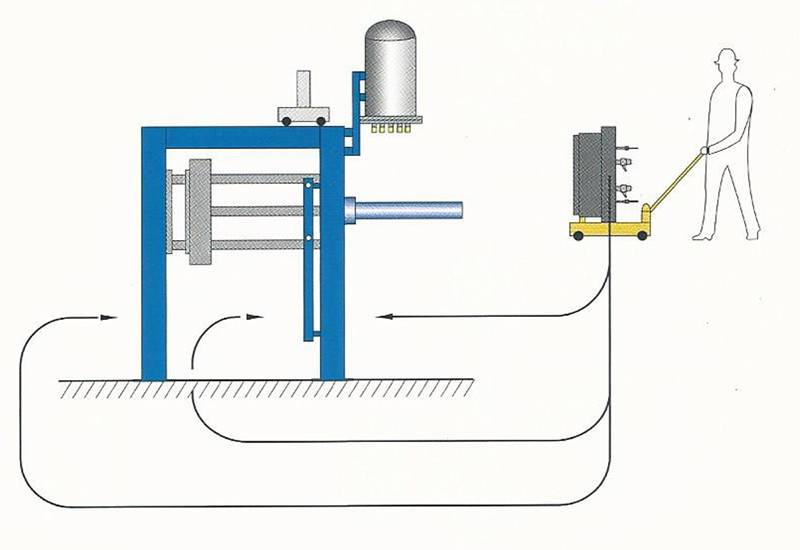

IHYDRAULIC SYSTEM

Uhlelo lwe-hydraulic olunezinyathelo ezimbili luhlinzeka ngesivinini ezimbili (esisheshayo futhi esinensayo) izinketho zokuvala isikhunta kanye nokuvula isikhunta.Futhi, isikhathi sokucubungula sincishisiwe.

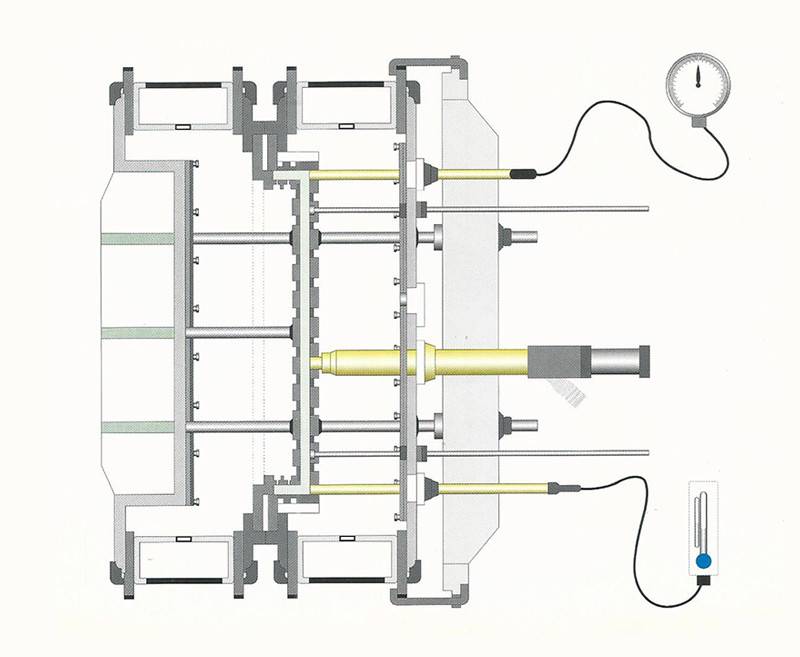

UHLELO LWAMANDLA OPHAKATHI

Lo mshini unesethi eyodwa egcwele yesistimu yamandla emaphakathi ekhiqizwa inkampani yethu Zonke izitimu nomoya odingekayo ngesikhathi sokujova zilawulwa yi-valve yesistimu yamandla emaphakathi.Lolu hlelo luzohlinzeka ngokungena komoya futhi lungalungiswa kalula.Lolu hlelo lwesitimu esinomfutho ophansi lwakhiwe ngamapayipi akhulisiwe namavalvu anganikeza isimo esingcono kakhulu sokusebenza.

I-DAMPER YOKUPHUMULA IMICINDEZI

Ukulungiswa komfutho wamandla kubaluleke kakhulu.Ngaphansi kwengcindezi ephezulu yesitimu, isikhathi sokukhiqiza sizokwelulwa futhi kudle amandla amaningi.Kodwa-ke, umkhiqizo wokugcina ungase ukhubazeke futhi ukubukeka kwangaphandle komkhiqizo kuphazamiseke uma ingcindezi iphansi kakhulu.I-damper yokusiza isebenza lapho ikhulula isikhunta futhi ishisa isikhunta.Umoya ocindezelweyo usetshenziselwa ukugcwalisa futhi le damper izonciphisa ukusetshenziswa kwamandla futhi inikeze umkhiqizo wekhwalithi ephezulu.

ITHENGI LAMANZI LOKUMAMBILA

Umshini ufakwe isethi eyodwa yokubamba i-hank yamanzi ecindezelayo enokufakwa okubili okuhlukene kwamanzi okupholisa kanye ne-condensate.

I-VACUUM SYSTEM

Isistimu ye-vacuum ifakwe iphampu ye-Liquid Ring Vacuum kanye ne-condenser ehlinzeka ngokuvuleka okusebenza kahle kakhudlwana.Ngaphandle kwanoma yisiphi isinyathelo esengeziwe sokumisa, singasheshisa umjovo ngaphansi kwalesi simiso se-vacuum.I-ejection yesikhunta kulula ukuqedwa futhi iphinde isindise amandla engeziwe.

UHLELO OLAWULO LWEKHOMPYUTHA

Lo mshini womjovo ufakwe isistimu elawulwa ngekhompuyutha enemisebenzi yokuhlela nokunweba.zonke izinyathelo zokusebenza zingaphansi kokulawulwa yileli phutha lokutholwa kwesistimu yekhompyutha futhi izinkomba ziboniswa esibukweni Yonke imodeli ifakwe nalolu hlelo lwekhompiyutha olubonisa izinqubo, ukusetha isikhathi kanye nokubalulekile kwevalvu yokulawula ukucindezela kuzobeka ukucindezela.

Amazwana:

Singakwazi ukuklama umshini ngokuvumelana nemfuneko yemininingwane yekhasimende.

Umshini we-EPP:

Umshini we-EPP Embonini Yamakhasimende:

Imikhiqizo: